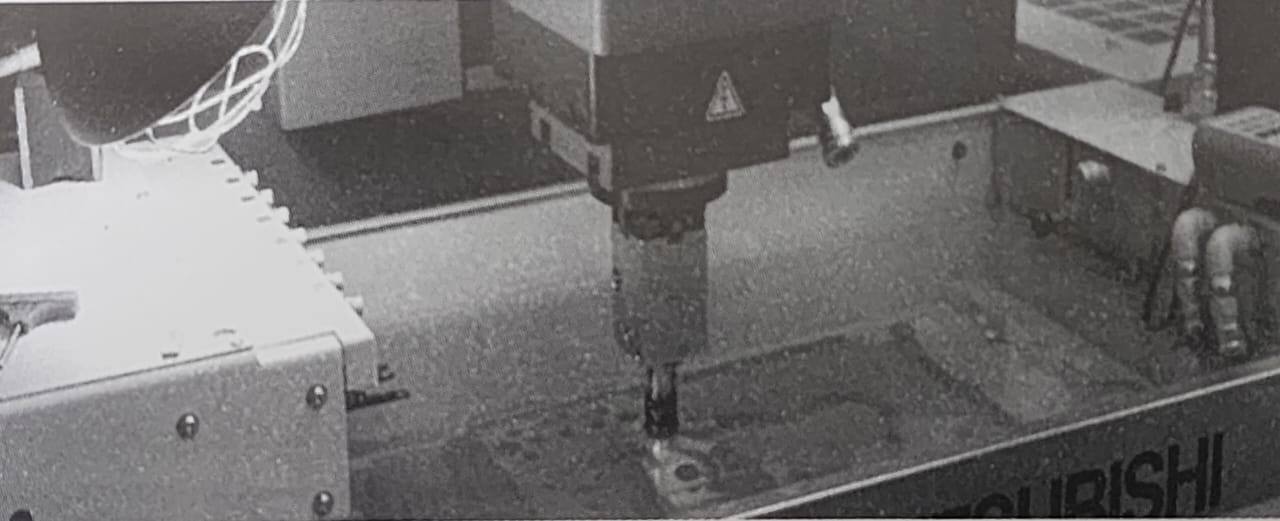

POC EDM oils are used as the working fluid in Electrical-discharge Machine (EDM) also called spark Erosion Machining. These oils have the ability to provide uniform insulation and then to permit controlled electrical discharge at the breakdown voltage. POC EDM oils also have the proper balance of viscosity, volatility, oxidation stability, heat transfer from characteristics and low odor and toxicity properties enables POC EDM oils of function of an insulator between tool and work-piece a spark conductor, a coolant and flushing medium for chip removal.

POC EDM Oils are used for insulation in between the tool and the work-piece as a special di-electric fluid. POC EDM oils are meeting the requirements for insulation and control di-electric discharge during electric discharge machining operations. The low viscosity of the product provides good circulation through the spark gap and more rapid removal and settling of metal fines. Recommended for plunge or ram electrical discharge machining and Glass grinding.

BENEFITS

. Better balance of Viscosity and Volatility

. High oxidation capabilities

. Excellent Heat Transfer Traits.

. Less odour and toxicity

. Higher Flash Point

. High Die-electric capabilities

. Excellent refining ability

| PRODUCT -Specifications | POC EDM 2 | POC EDM 5 |

| Appearance | Apparent | Apparent |

| Kinematic Viscosity@40°C | 2.0-3.0 | 0.8-0.12 |

| Flash Point | 90 | 150 |

| Acid Number,mg/KOH gm, Max | 0.1 | 0.05 |

| Density @ 29.5 deg.C, in gm/ml | 0.816 | 0.824 |